Our Products

FEATURES

- Available Range – 5L – 1000L

- Validation compliant for certification

- Customised solution for user-friendly approach

- Compact modules for space

- Integratable units for convenience

- Cost-effective for projects

- Better & higher yield for good results

- Automated controls for process controls

FEATURES

- Available Range – 1L – 1250L

- Scalability

- Design based on principles such as

• Froudes no

• Tip speed

- Optional automated lid opening and blade lifting operations

- Tangential blade assembly with inclined profile for mass movement and

better mixing

- Inline Cone mill (Optional)

- Torque Measurement

- 21 CFR compliance automation

FEATURES

- Available Range – 1L – 1200L

- Scalability

- Improved design for higher efficiency

- FBE & FBP models

- Conidur sieves for better air flow and better drying

- Top & bottom spray options

- Stand alone and continuous options

- Containment system for ONCO, OEL & hormonal drug

- 21 CFR compliance automation

FEATURES

- Available Range – 1L – 5000L

- Variable Capacity ranging from 1L to 5000L

- Scalability maintained between sizes

- Customized design for better blending Fixed and lifting options

- Single and twin column options

- 21 CFR Compliance Automation

- Mobile and Stationary Options in Lab Models

TYPES

- Umbrella Dryer

- Insertion Dryer

- Cupboard Dryer

FEATURES

- Uses Centrifugal force for both Milling and Sifting

- Gentle grinding action with close particle size distribution

- Minimal fines generation

- Charging of material- either gravity fed or vacuum transferred

- Increased throughput with 50% more capacity than conventional mills

- Adaptable & flexible design with interchangeable Cone mill and Rotary sifter and through the wall design

- Customised options for feeding and handling

- Readily available scale up from lab to production scale

- Material of construction : SS 316 / SS 316L / Food grade materials

- Easy to clean

FEATURES

- cGMP Model with contact parts in SS 316 & Non-Contact Parts in

SS 304

- Amplitude of Vibratory Motion adjustable

- SS 316 Hood with 200 mm dia Nozzle for dust free charging of

Powers

- Easy dismantling, cleaning assembling through quick opening

SS 316 clamps

- Portable mounted on sturdy Castor Wheels

- Vibrating assembly isolated by rugged springs

- Dust-free design

- Independent Jacks for lifting the machine off the floor for effective sifting

FEATURES

- cGMP Model with contact parts in SS 316 & Non-Contact Parts in

SS 304

- Amplitude of Vibratory Motion adjustable

- SS 316 Hood with 200 mm dia Nozzle for dust free charging of

Powers

- Easy dismantling, cleaning assembling through quick opening

SS 316 clamps

- Portable mounted on sturdy Castor Wheels

- Vibrating assembly isolated by rugged springs

- Dust-free design

- Independent Jacks for lifting the machine off the floor for effective sifting

FEATURES

- Variable capacity (12” to 72” pan size)

- Scalability

- Improved design for higher efficiency Best in class spraying system

- Zero tablet discharge

- Pan design based on volume calculations

- Containment system for ONCO, OEL & hormonal drug Compatible for usage with PAT and NIR instrument

- 21 CFR compliance automation

FEATURES

- CONTACT PART SS316L MATERIAL

- Equipped with Heat transfer, insulation and sheathing capabilities

- Customised as per Clients Requirements.

- Additional accessories such as Load cell arrangement, Level Sensor, pressure control etc. options available

- Mobile and stationary options

- Design as per ASME Section VIII-1 guidelines

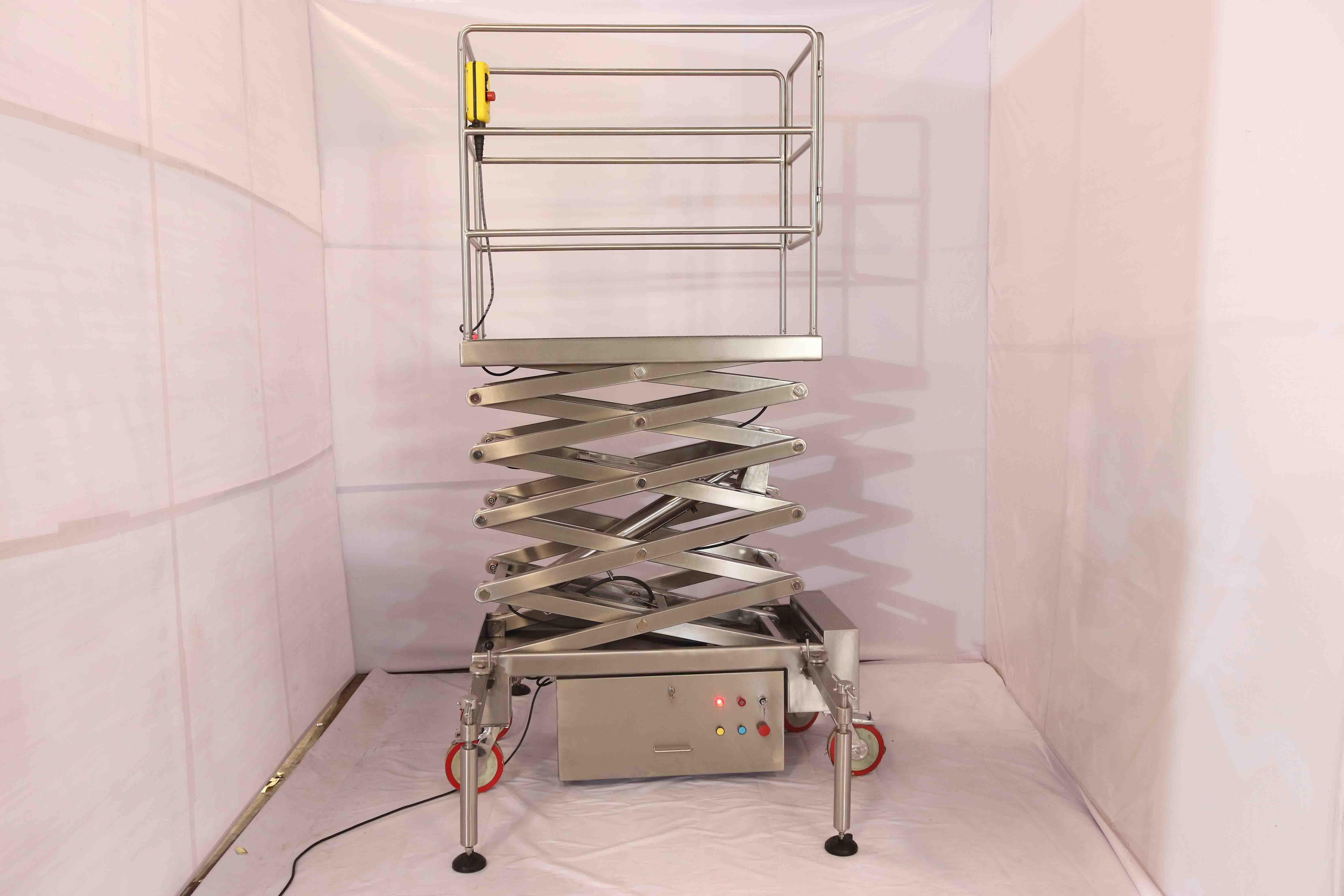

FEATURES

- Closed Column construction with floor and ceiling fastening

- Also available in self-standing pivoted execution

- Material of construction is SS clad MS column/SS column

- Adjustable mount stop

- Double acting in-house manufactured Hydraulic Cylinder with 3 stage Fail safe seals

- Cylinder designed for an operating pressure of 100 BAR & has a Hose burst protection system

- Lift Lock for safety provided

- Imported Mono Block Power Pack

- Control Cabling and rigid piping included

- Built-in provision for the Vibratory Sifter/ Mill to be electrically connected

- Mechanical & Pneumatic locking for Safety

FEATURES

- Available Size – 5Kgs – 1000Kgs

- Scalability

- Single & multi vessel design with interchangeable customized units

- Stationary and mobile options

- Compact ergonomic design

- Automized operative controls

- Pat enabled units

FEATURES

- Three Tank process – Sugar Melting vessel, Syrup Manufacturing Vessel and Storage Vessel in SS304/SS316 and SS316L

- Jacket for Steam Heating / Electrical Heating is optionally provided for Hot Process

- Homogenizer for homogenous online / inline mixing of products / Suspensions Liquid Homogenizer / Stirrer Optional

- Electropolished interconnecting pipeline and TC fittings for easy cleaning & Assembly

- Complete untouched process optional with Auto Transfer of products and ingredients

- Optional vacuum arrangement provided on requirement.

- Control Panel – Standard Control Panel / Digital Control Panel is provided with the plant which included on/off switches for stirrer, homogenizer, Pumps, Filter Press and Thermostatic Controller for Heating System conveniently fitted with easy reach of operator

- PLC operated control panel system Optional

FEATURES

- Closed Loop Transfer System.

- Faster Operation

- Compact Design

- Customized as per Client requirements

- Cost Effective

- Reduces Production Time thus

Increasing Production rate higher

transfer Capacity up to 2500 kgs / hr.

FEATURES

- Designed uniquely for optimum mixing efficiency

- Special stirrer included for homogenous mix

- Controlled temperature exposure with special jacketed bowl

- Variable rotation rates possible

- Available in custom made capacity

- Jacket – steam / electrical heater type

- Manually / Motorised tilting arrangement

- Direct transfer of binder solution to granulation processing equipment. (optional)

- Easy cleaning & maintenance

FEATURES

- We design & supply Mobile and fixed CIP & SIP Units for sanitization and sterilization

- The units are custom made, modular. Skid either automatic or semi- automatic models as per equipment’s for cleaning and sterilization.

- Jacketed /non-jacketed tanks

- Heaters / Steam as required

- Inter connecting Piping’s/Valves/Instrumentation

- Complete automated process through PLC System for recipe type functions

- Efficient circulation of cleaning medium such as purified water, hot water, detergent solution with special provision of sanitization along with drain and flush cycles

.jpg)

.jpg)

.jpg)

.jpg)