Skyline Rapid Mixer Granulator

Skyline Rapid Mixer Granulator is designed to meet special needs of tablet formulation technology.

This is achieved by reducing processing time, homogeneous mixing, even distribution of binder,

wetting, nucleation and granule size growth with sampling provision for in process analysis and proven

safety during processing, compliant to cGMP norms.

Working Principles

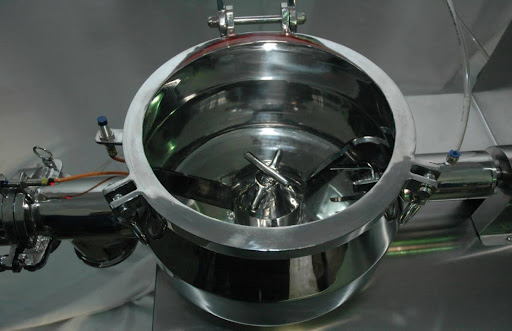

>> RMG consists of a Mixing Bowl, Impeller, Chopper and Outlet.

>> The mixing Bowl of the rapid mixing granulator consists of Top Conical part and Bottom Cylindrical part with Flat Dished Bottom.

>> The main purpose of this shape is to eliminate dead corners and wall sticks and the binder mix well with the granules.

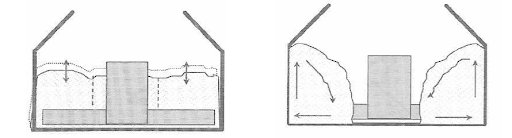

>> Rapid mixture granulator works on agitation and tumbling.

>> The impeller is responsible for uniformly mixing wet granules, and the chopper helps in breaking or reducing particle size. At the starting process or during binder addition, the impeller and chopper generally operate at low speed. Then after the formation of wet mass, they are operated at high speed to make the desired granule size.

Impeller

>> The speed of Impeller should be high enough to cause Roping flow motion as

slow speed causes Bumping motion of powder and leads to Inefficient mixing.

>> At higher speed of Impeller, size of granules increases and if high speed is for

longer time due to continuous collisions between the particles the size of

granules will decrease.

>> The gap between base of mixing chamber is around 2.0 mm which is enough that the granules pass below the impeller blade without breaking.

Chopper

>> The use of chopper should not be done always as we know the chopper will break the granules.

>> Firstly look weather active is free flowing or cohesive , weather it lumps or not .Chopper should be used if active is cohesive or forms lumps at the minimum speed after solution addition .

Binder solution

>> Binder should be added slowly not suddenly as sudden addition of binder leads to inefficient distribution of binder and may cause hardness variation in tablet.

End Point

>> Ampere load on Impeller and Chopper i.e the current which is used by Impeller and chopper motor to rotate when granules are formed. Ampere load is high in beginning when granulation starts as motors need more power and decreases as end point is reached.

- The Mixing Bowl consists of Top Conical shape and Bottom Cylindrical shape with flat Dish at the bottom.

- The purpose of this shape is to reduce dead corners and material sticking to the wall.

Mixing Bowl

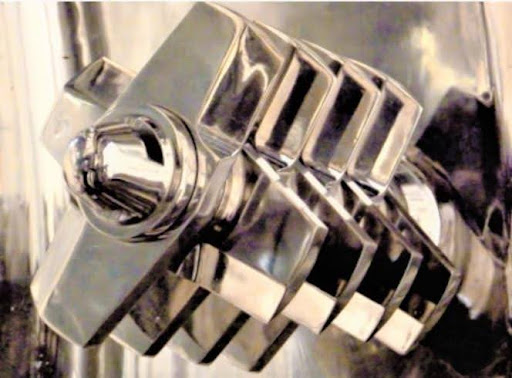

- Strategic Z shaped impeller scrap and lifts the material upward which help in faster granulation.

- Z shaped blade imparts less force on drive shaft. Hence minimizes load on motor.

“Z” Type Impeller Blade

- Knife edge chopper design

- Improved chopping time

- Easy dismantling of assembly for cleaning

New Chopper Blade Design

Features

- Variant capacity (1L to 1250L)

- Scalability

- Design based on principles such as

• Froudes no • Tip speed - Optional automated lid opening and blade lifting operations

- Tangential blade assembly with inclined profile for mass movement and better mixing

- Inline Cone mill (Optional)

- Torque Measurement

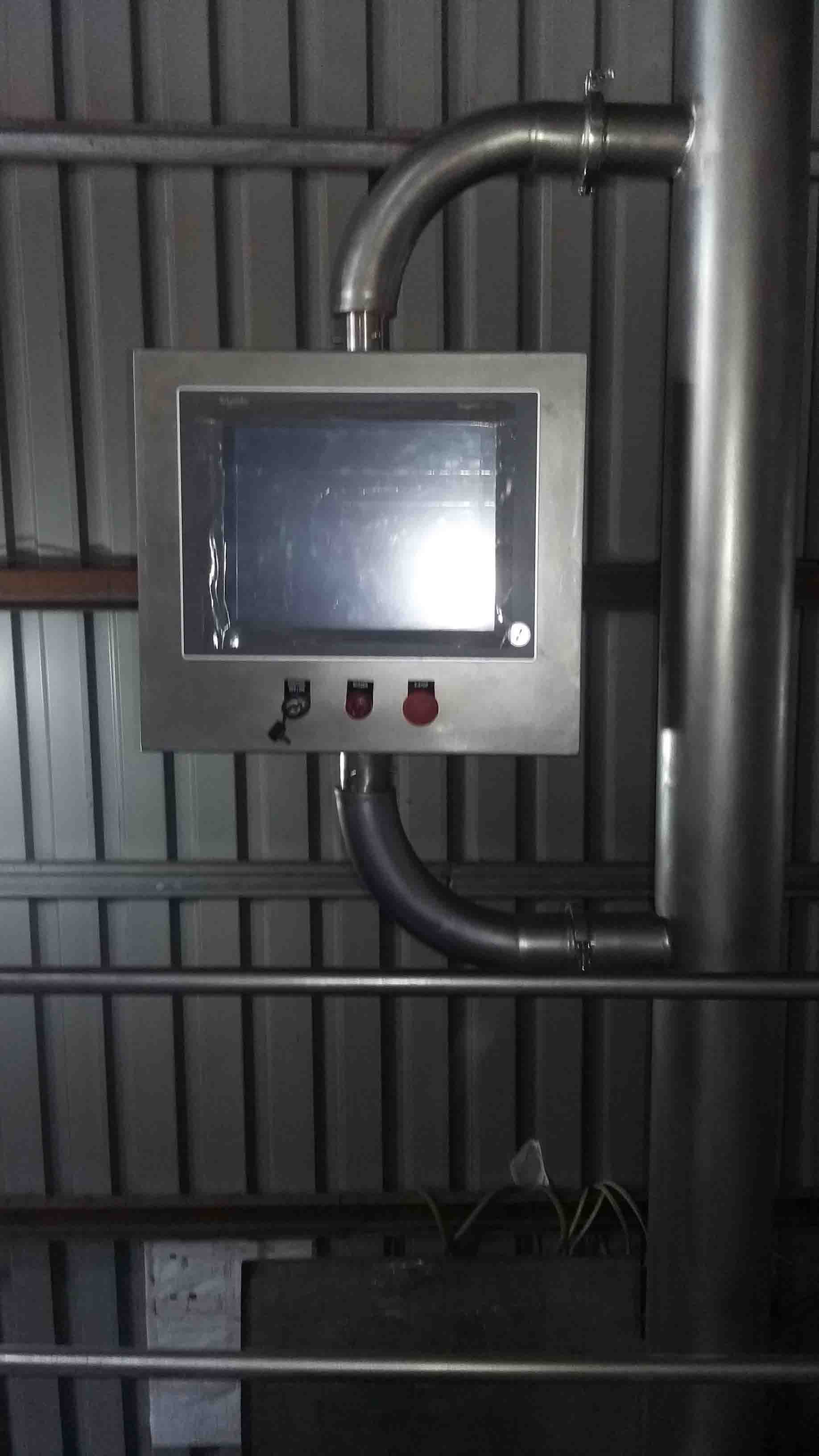

- 21 CFR compliance automation

.jpg)